NJSSOLUTIONS your business endeavors

Baristo, a top vending machine provider in Georgia, faced significant issues with a machine from an external company, impacting customer satisfaction and efficiency.

Case Highlight

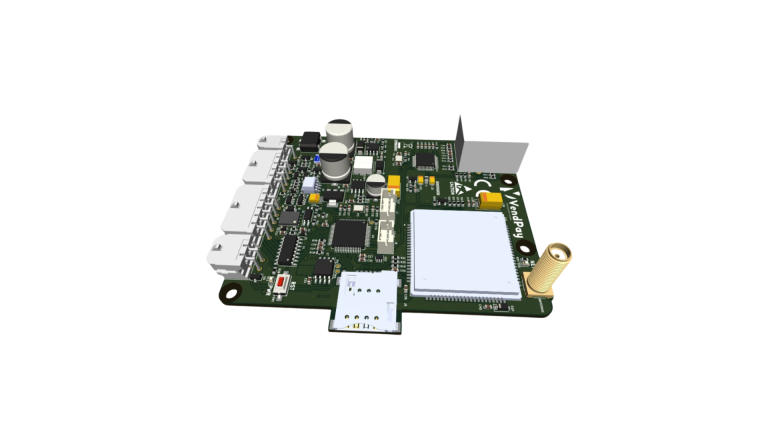

This comprehensive hardware overhaul, facilitated by NJSSOLTIONS, not only resolved the initial malfunctions but also positioned Baristo to offer more reliable and cost-effective vending solutions to their clients. With the improvements in technology and operational efficiency implemented by NJSSOLUTIONS, Baristo maintained its competitive edge in the market, reinforcing its reputation as a leader in the vending machine industry

Device Slow Operation: Users experienced delays, affecting transaction times and overall user experience.

Increased Cellular Internet Traffic: The machines used excessive data, leading to higher operational costs and inefficiencies.

High Monthly Rent Cost: The cost associated with leasing these machines was not aligned with the value provided due to these ongoing issues.

Problem

The vending machines experienced several key malfunctions that compromised their functionality:

Solution

To resolve the identified issues, a comprehensive hardware service overhaul was initiated, focusing on enhancing machine performance and cost-efficiency: